Introduction

As RF power technologies continue to evolve, managing thermal performance remains a key factor in ensuring optimal operation and reliability. ART LDMOS transistors, known for their ruggedness and efficiency, require precise thermal characterization to meet performance targets across a range of operating conditions. A consistent and standardized approach to evaluating thermal behavior helps improve design outcomes, system stability, and long-term reliability.

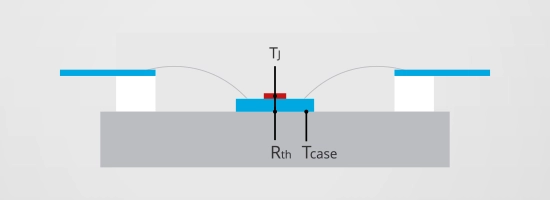

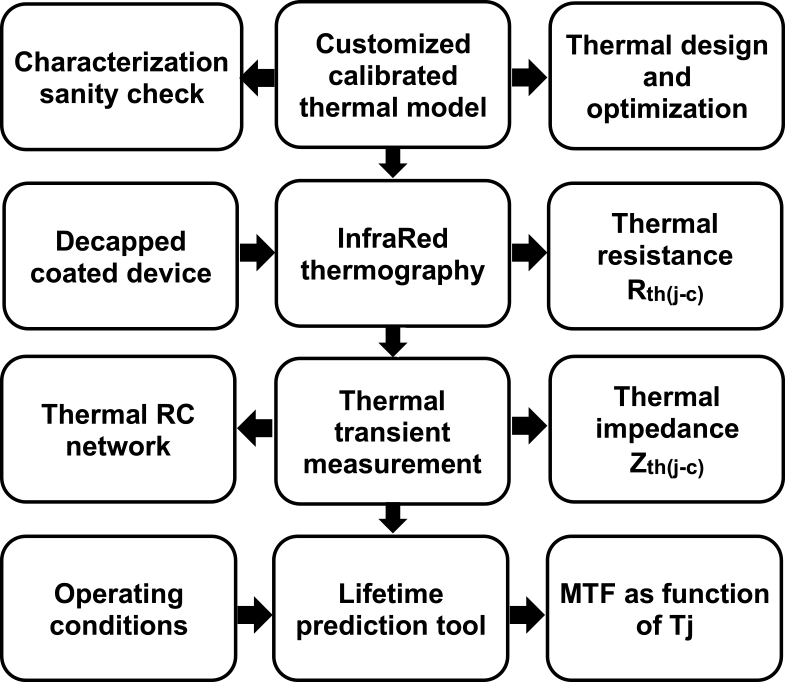

The steady-state thermal resistance between the junction and case, typically denoted as Rth(j-c), plays a central role in estimating the junction temperature during operation. Accurate values are obtained through infrared thermography, which captures the temperature distribution across the die surface under controlled power dissipation.

This measurement technique ensures alignment with established reliability testing standards, providing confidence in the thermal model used for system-level analysis. With a reliable Rth(j-c) value, the junction temperature can be derived accurately based on the case temperature and power dissipation.

Thermal behavior is not static, especially in systems with varying duty cycles, pulse power levels, or dynamic load conditions. To represent this, the transient thermal impedance Zth(j-c)(t) is extracted through time-domain measurements that reflect the dynamic response of the device.

This data is often modeled using a Cauer-type RC network, which offers a physically meaningful representation of the heat flow path from the junction to the case. Such models are particularly well-suited for simulation environments, enabling thermal interaction to be incorporated directly into electrical and mechanical simulations.

Some devices in the ART family incorporate a temperature sensor embedded within the die. This sensor typically provides a current output correlated with the junction temperature, allowing for direct monitoring without the need for additional components or external sensing mechanisms.

Key benefits include:

- Real-time junction temperature feedback

- Minimal footprint and circuit complexity

- Fast response for dynamic protection strategies

These capabilities enable more effective thermal management strategies at both the design and operational levels.

Thermal conditions have a direct influence on long-term reliability. By combining thermal modeling with empirically derived activation energies, a mean time to failure (MTF) estimate can be calculated based on the operating temperature profile.

This estimate is commonly expressed in terms of failure-in-time (FIT) rates. These rates provide a quantitative way to compare the expected reliability of devices across different thermal environments or usage patterns.

Using this predictive approach, it is possible to balance performance with lifetime expectations early in the design phase, reducing the risk of later-stage reliability issues.

A well-defined methodology for thermal evaluation supports several key advantages:

- Accurate junction temperature estimation during both design and verification

- Integration of thermal dynamics into simulation and modeling environments

- Early detection of thermal constraints and design optimizations

- Improved alignment with long-term reliability targets

By applying these techniques, thermal considerations can be managed more precisely and effectively throughout the development and operational lifecycle of RF power systems.

About the author

Amir is a thermal modeling and characterization expert at Ampleon. He provides technical support to ensure products maintain optimal thermal performance and reliability over their lifetime.

Principal Thermal Engineer

Committed to your success

During the entire process from design to delivery, we provide a range of support options to address your needs. Whether you require load-pull data, application boards, samples, ADS / AWR models, assistance with a complex design challenge or seek quick advice, we are on stand-by to support you. Our application engineering resources are spread around the globe, with our offices in Nijmegen / The Netherlands, Toulouse / France, Smithfield / USA, and Shanghai / China.

This tool provides reliable lifespan data, shown as Median-Time-To-Failure (MTF) based on Junction Temperature (TJ), assuming electromigration as the primary wear-out mechanism.

This tool provides real-time and precise data calculations for Junction Temperature, Thermal Resistance, Minimum Efficiency, and Thermal Efficiency.

Ampleon's ART transistors are specifically engineered to deliver the best in terms of RF power, gain and efficiency, but more importantly, they boast crucial ruggedness and reliability features that set them apart from the competition.